£1.1 million boost for Sussex quantum team leading the green tech revolution

By: Anna Ford

Last updated: Thursday, 3 December 2020

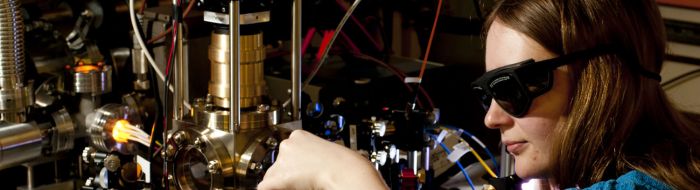

Prof Peter Kruger with the vacuum chamber in the quantum sensing lab

- Sussex’s breakthrough research on electric car battery sensors has seen their collaboration land £5.4 million in funding, with £1.1 million going to the Sussex partnership.

- Scientists at the University of Sussex work side-by-side with commercial partners CD02.

- It’s a quantum leap for the team who are focussed on finding green solutions to global challenges.

Quantum scientists at the University of Sussex have won major government funding to develop sensors for electric batteries. They, along with their industry partners, attracted £1.1 million in funding, with their wider collaboration securing a total of £5.4 million. It’s a significant win for the team as the aim of the overarching project is to commercialise research originally done at the University of Sussex.

The team of physicists, led by Prof Peter Kruger, announced in 2019 that they had produced the world’s first quantum sensor for electric batteries. They work alongside a company called CDO2 – located at the Sussex Innovation Centre on the University of Sussex campus - which was founded by Dr Gary Kendall. The company works to commercialise the physicists’ research. This project builds on work started by the pairing in 2018 with a £455k project from the Faraday Battery Challenge.

The funding win is part of Innovate UK’s total £23 million investment. The project – which will include further research, and the development of an commercial supply chain for electric batteries - is part of the government’s ‘Commercialising Quantum Technologies’ programme.

Together, the Sussex partnership will build quantum sensors to test the health of electric batteries. The development will streamline the battery development process. Normally, electric batteries are left to develop at a warm temperature and are assumed to be ready after several weeks. But with the new quantum sensors, the batteries can be tested for their readiness in real-time, potentially speeding the production process from weeks to days. This means they’ll be useable more quickly, and that more batteries can be created in the meantime. It’ll save factory space and energy costs too.

The three year project will see a pilot production facility established in Thurso in Scotland, before a new ‘Gigafactory’ is built to make the batteries. The University of Sussex will be home to a prototype of the new battery sensor.

Professor Peter Kruger from the School of Mathematical and Physical Sciences at the University of Sussex said:

“We’re thrilled that the research we pioneered at the University of Sussex is driving this project and providing sustainable solutions in the race to switch from fossil fuels to electric power. We developed the underlying technology in our laboratory at the University of Sussex, where we use quantum sensors to create an image of what’s happening inside the battery. Previously, the only way to see inside such a battery was to open it up.

“Our work has important sustainability benefits: our research will increase the recyclability of batteries, and prevent useable ones from being unnecessarily discarded. And it will bring energy savings in the production process too, as the batteries will not need to be housed at high temperatures for so long.

“Over the last few years we have developed a symbiotic relationship with our commercial partners CDO2 crossing boundaries where we are now seriously linking industry and academia.”

Dr Gary Kendall, founder at CD02 said:

“It is very exciting to have such widespread support for the development of this new technique for end-of-line testing of battery cells that we developed with the University of Sussex. We are looking forward to working across the quantum supply chain in the UK to turn it into a commercial product for battery factories worldwide.”

Electric vehicles are predicted to comprise 20 per cent car sales by 2026, which means the demand for batteries will undoubtedly rocket. And it is reported that the UK government is poised to bring forward its ban on new fossil fuel vehicles from 2040 to 2030. There is a global race to use quantum technology to solve urgent problems, and this project is an important part of the UK’s response to that.

The project is being led by AMTE Power who are building the first “Gigafactory” for battery cell production in the UK. The full list of partners in the project is: Compound Semiconductor Centre Ltd, Magnetic Shields Ltd, Compound Semiconductor Technologies, Alter Technology, Kelvin Nanotechnology Ltd, and Centre for Process Innovation, CDO2, University of Strathclyde, and the University of Sussex.

Additionally, a separate and related project aimed at harnessing quantum technology to enhance vehicle battery performance has been awarded £270,000 in Partnership Resource Funding by the University of Birmingham-led UK Quantum Technology Hub Sensors and Timing.

The project, led by University of Sussex researchers who have been awarded £215,000 of the grant, addresses a need to increase battery energy density, longevity and safety.